Welcome...

Buffer Stock Blending

The IPEC Buffer Stock Blending (BSB) System offers an innovative way to prepare buffers for use in biopharmaceutical manufacturing. It provides significant cost savings, reduced facility footprint, and increased flexibility. It is the ideal solution for any biopharmaceutical manufacturer looking to improve their efficiency and productivity.

Buffer Stock Blending

The Problem

Traditional methods for preparing biopharmaceutical buffers require significant capital cost, floor space and time, often resulting in production bottlenecks. In 2019 IPEC was invited to assist a consortium led by NIIMBL and BioPhorum with the design and fabrication of a system used to evaluate the effectiveness of a new concept for on-demand buffer production.

Traditional Buffer Prep Super Skid

Buffer Stock Blending

The Solution

The system realized through the consortium efforts provides on-demand buffers using common stock concentrates, eliminating the need for large centralized buffer preparation facilities. The system is flexible and scalable, making it ideal for use in a variety of manufacturing settings. A subsequent validation study concluded that the BSB platform meets or exceeds the initial design goals for acceptable use in cGMP manufacturing.

NIIMBL-BioPhorum Study Findings*

- Up to 150X dilution possible (dependent on stock concentrations)

- Time of start-up/balancing to dispense of 15-45 seconds

- Low stock concentrate waste of (<5% @200L batch, <1% @3000L)

- Greater than 99% compositional accuracy possible (dependent on volume dispensed)

- Downtime < 2 minutes between product changeover

- Significant decrease in both CAPEX & OPEX possible

*See links to articles, etc. in the Resources Section below

NIIMBL-BioPhorum BSB Pilot System

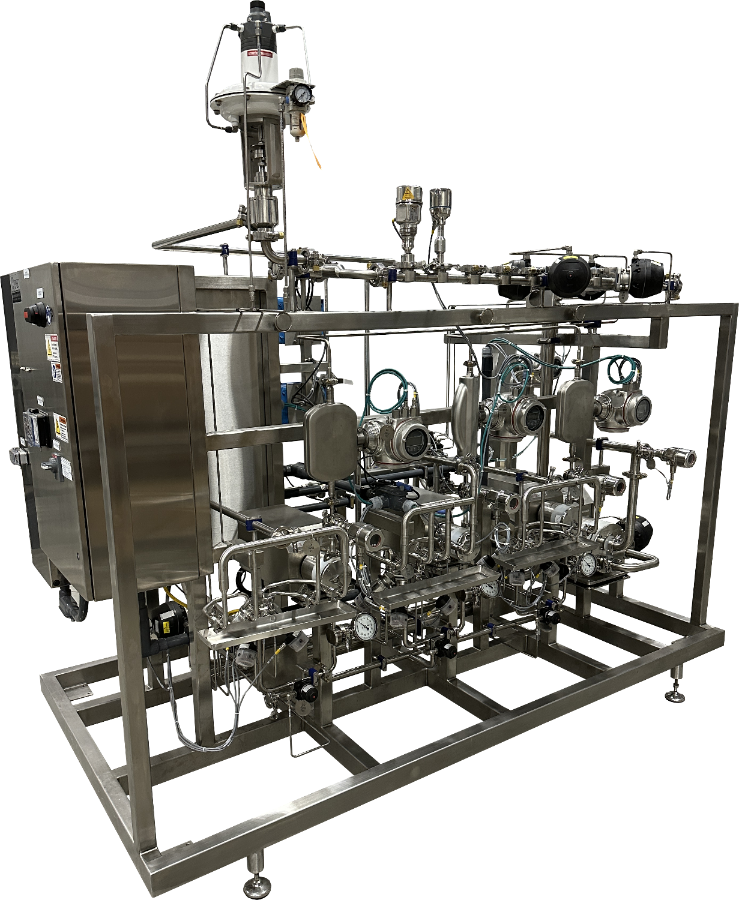

IPEC Gen2 BSB System

Buffer Stock Blending

Continued Innovation

While the data and design resulting from the initial NIIMBL-BioPhorum efforts are open-source, IPEC has since incorporated a number of improvements into a next-generation design. Please contact us to discuss your next project.

IPEC BSB - Next-Gen Improvements

- Reduced system footprint/hold-up volume

- Line size modifications for improved system hydraulics

- Increased maximum system flow rate/capacity

- Updated concentrate feed line flushing design

- Pump speed control & feedback improvements

- Additional dispensing outlet

- Installation sensors/safety interlocks on CIP Jumpers

- Increased system pressure rating and improved pump overpressure protection

IPEC BSB - Standard Features

- Up to 80 lpm pump WFI for dilution

- (3) concentrate supply pumps up to 20 lpm each

- Digital communications for process-critical instrumentation and components

- Mass balance/flow-based dilution

- Improved automation/recipe management platform

- Hybrid 316L SS/Hastelloy-C wetted construction

- Self-CIP

- 21 CFR Part 11 compliance

IPEC BSB - Next-Gen Options

- WFI Break Tank

- Low-flow inlet (3 lpm) for more dilute solutions or higher concentration stocks

- Additional inlet pumps

- Additional inlet ports

- Additional outlet ports

- Additional valving and instrumentation to support full chromatography proccess

- Other general customizations available

Buffer Stock Blending