Welcome...

About IPEC

At IPEC, it is our mission to provide the highest quality service, systems, and support. We will continue to improve our procedures and techniques in order to thrive in the most competitive markets while maintaining our commitment to the end user. We thank our dedicated employees and loyal customers without whom we could not succeed.

About Us

1996

IPEC was founded in 1996 in Fort Atkinson, WI to serve the food and dairy industry.

About Us

2001

In 2001 our scope of services were expanded by completing procedures and specifications required to serve pharmaceutical and biotech markets.

About Us

2003

We relocated to our current building in 2003. The 51,000 square foot facility was designed to support state-of-the-art services for our clients and their respective industries.

About Us

2016

In 2016, IPEC celebrated its 20th Anniversary with a facility expansion. The addition increased manufacturing space and roof height allowing us to manufacture complete & upright systems taller than previously possible.

About Us

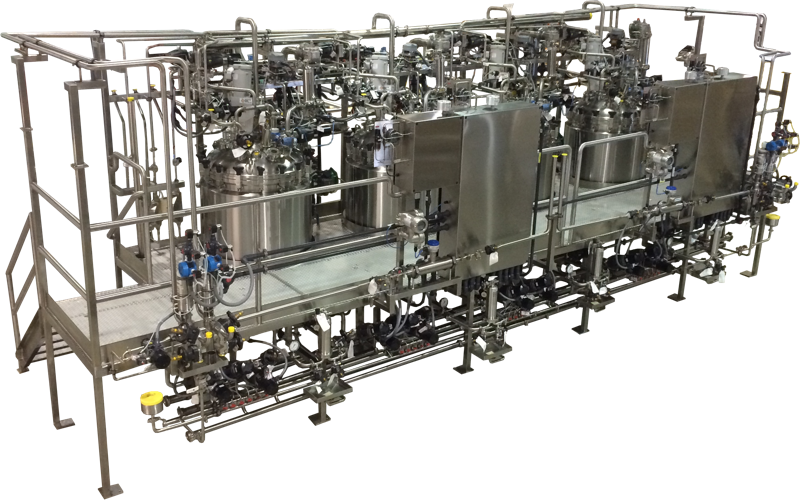

Shop

Our fabrication floor includes over 41,000 square feet of manufacturing space carefully designed to meet the expectations of our most demanding customers.

IPEC Production Facility:

24 & 35 foot under-beam ceiling height

Aides in filling the vessel with steeping water and minimizing dust during loading.

Dual overhead cranes

Our design provides effective rousing and grain mixing without the use of mechanical agitation.

Loading/receiving docks

An overflow port near the top of the vessel allows for removal of floating debris which is collected in a screen accessed at ground-level.

Multiple overhead doors

Process valves are included for water addition, water draining, CO2 removal, and casting. Instrumentation is provided to monitor air pressure, temperature, etc.

Secure stock area

This blower is operated during Air-Rest to displace CO2 produced during grain respiration.

Segregated grinding, carbon steel, and electrical assembly rooms

Steeping Vessels may be manually operated, or as fully automated AutoSteep™ Systems which include configurable recipe management.

About Us

Testing

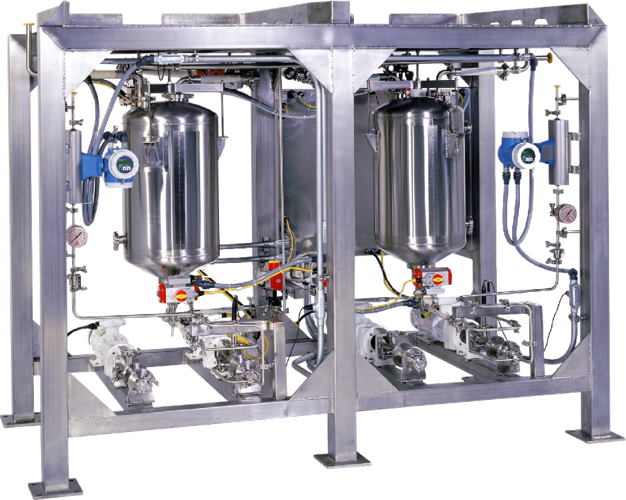

Our multiple wet test areas provide ample space and utilities for factory acceptance testing (FAT) and other pre-validation services.

IPEC Test Areas:

City, Softened & Deionized Water

Aides in filling the vessel with steeping water and minimizing dust during loading.

Plant, Filtered & Clean Steam

Our design provides effective rousing and grain mixing without the use of mechanical agitation.

Clean Compressed Air

An overflow port near the top of the vessel allows for removal of floating debris which is collected in a screen accessed at ground-level.

Trench Drainage

Process valves are included for water addition, water draining, CO2 removal, and casting. Instrumentation is provided to monitor air pressure, temperature, etc.

480 VAC 3-ph & 120 VAC power

This blower is operated during Air-Rest to displace CO2 produced during grain respiration.

Generation of power for international systems (50 Hz, etc.)

Steeping Vessels may be manually operated, or as fully automated AutoSteep™ Systems which include configurable recipe management.

About Us

Guests

Our facility includes multiple customer conference rooms, designed to provide comfort and convenience for our visitors.