Welcome...

Craft Malt

IPEC Malting Systems are designed for those who demand the highest quality equipment and process control. Through a combination of time-tested and innovative methods, we empower Maltsters to grow the emerging Craft Malt industry. Manufactured in Wisconsin, USA, our systems are the result of detailed engineering, advanced technology and superior craftsmanship.

We offer standard equipment designs over a range of batch sizes, but our strength as a custom fabricator/integrator can be leveraged to manufacture a system or individual components to your exact requirements.

Craft Malt

Gallery

All-In-One

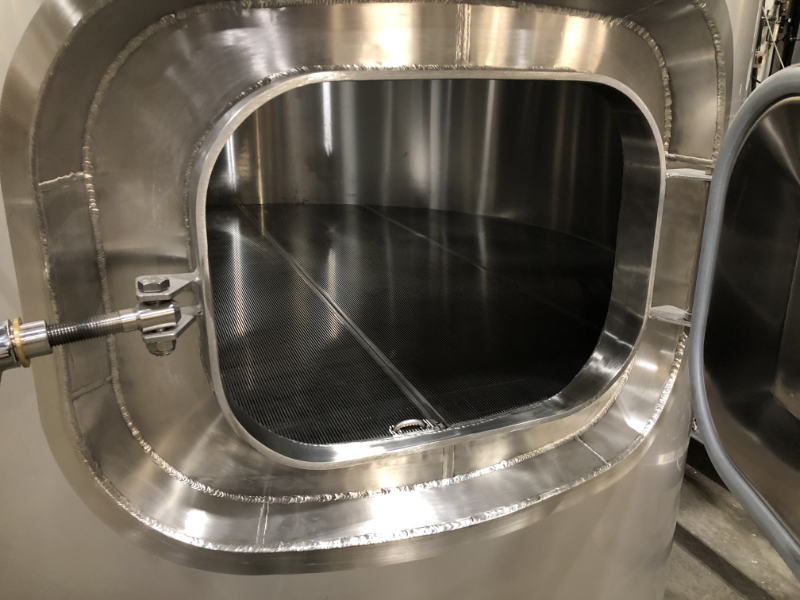

The fully-insulated, 100% stainless steel Malting Vessel can process between 1 and 4-tons of raw grain and includes the agitator, unloading doors/manways, wedgwire false-floor, plenum chamber, aeration nozzles, instrumentation and cleaning devices. These features provide a robust and clean environment in which to facilitate all phases of the malting process.

All-In-One

The fully-insulated, 100% stainless steel Malting Vessel includes loading & unloading doors, wedgwire false-floor, plenum chamber and aeration nozzles. These features provide a robust and clean environment in which to facilitate all phases of the malting process.

Grain-Turning

At the core of the AutoMalt™ is a patent pending agitation system responsible for one of the most critical (and toughest) jobs within the system - Gently turning the grain during processing while improving air flow and maintaining even humidity and temperature distribution.

Forced-Air Malting

IPEC Craft Malting Systems use industrial-grade blowers to push conditioned air through the grain bed during various process steps. Each fan is conservatively sized based on the batch volume, grain depth and customer location (elevation) to ensure proper capacity. Variable speed drives are included to enable precise control of air flow during low flow (germination) and high flow (kilning) phases.

Process Cooling

A liquid-to-air heat exchanger is used to lower process air temperature as needed during germination sequences using chilled media supplied from an external chiller.

Process Heating

Process air is heated using an efficient, indirect-fired furnace which may be configured for natural gas or propane. Each heating system can be designed to provide proper heating during Free-Dry, Force Day and Curing without recycling humid off-air, based on the customer's location and seasonal outdoor temperatures. Steam heat exchangers are also available if your facility includes a boiler system.

Process Heating

Process air is heated using an electric element which provides precise control using the Operator-defined set point and PID controller. Standard sizing is sufficient for most applications, but capacity can be adjusted to suit specific requests.

Optimal Steeping

A process water cooler is included for use in lowering steep water temperature as the vessel is filled. This heat exchanger uses the same chilled media as the process air cooler and can be manually adjusted as needed for seasonal variations in water or grain temperature. Alternatively, a process water heater can be included if winter water temperatures result in sub-optimal steeping conditions.

Process Humidification

The stainless steel Misting Chamber humidifies process air using atomizing spray nozzles. Multiple zones & nozzles are included to allow for flow rate adjustments based on variable seasonal/ambient conditions. This ensures effective humidification without excessive water waste.

Integrated Clean-In-Place

With purchase of the optional CIP Cart, Malting Vessels & Kilns can automatically and consistently be cleaned-in-place using the integral spray devices, further minimizing downtime between batches with a configurable recipe, heated detergents, and flow monitoring.

Take A Load Off

The innovative mixer design also dispenses cured malt from the Vessel through the unloading door and into your grain handing system where it can be further processed (de-culmed, roasted, bagged) before sale.

Debris Removal

The system can automatically direct water and floating debris through an overflow weir during each wet steep filling process to reduce or eliminate manual efforts to skim "floaters" from the desirable grain. This function can be enabled and adjusted for durations based on grain quality and pre-batch washing/seed cleaning efforts to limit water waste.

Debris Removal

The MiniMalt™ includes a vessel spray ring and nozzles designed to direct water and floating debris through an overflow weir during each wet steep filling process to reduce or eliminate manual efforts to skim "floaters" from the desirable grain.

Flexible Controls

Affordable, yet helpful controls make the malting process easier to master. This includes timers for aeration and CO2 extraction, an adjustable blower speed dial and PID temperature controllers for heating and cooling sequences. Additionally, there are multiple safety interlocks to prevent certain activations from occurring at the same time (i.e. the blower and heater may not operate when the tank is full of water). An optional PLC and touchscreen are available for full automation, recipe management and remote access capabilities.

Know Your Weight

Optional load cells may be installed on the tank legs for use in confirming grain weight, if loading from a bulk storage system.

Maintain Steep Temperature

If your facility includes both plant hot and cold water supplies, a blending valve and additional probe can be integrated to facilitate precise temperature control when filling the vessel during each wet steep. This can be very useful to overcome issues associated with seasonal variations in water and grain temperatures, depending on the water source and location of raw grain storage.

Simple Process Transitions

Several ports attached to the tank bottom facilitate easy process control when moving through the various steps required for proper steeping, A stainless steel, cylindrical wedgewire screen allows steep water to be released through a drain port while preventing the escape of grain. A second, isolated port on this drain line is connected to the included industrial blower to provide the air flow required for heat and CO2 extraction from the grain during air rest. A liquid-tight knife gate or butterfly valve is installed on the main cone outlet for use in cast-out upon completion of the steeping process.

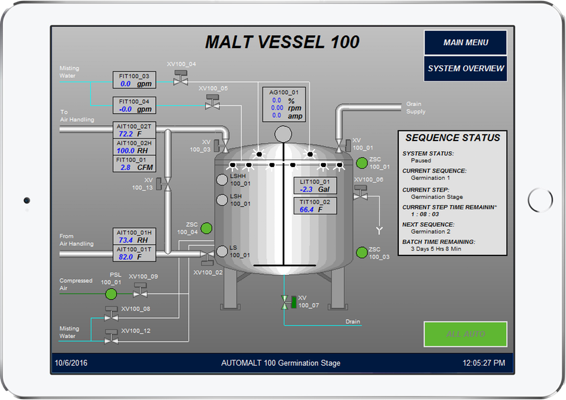

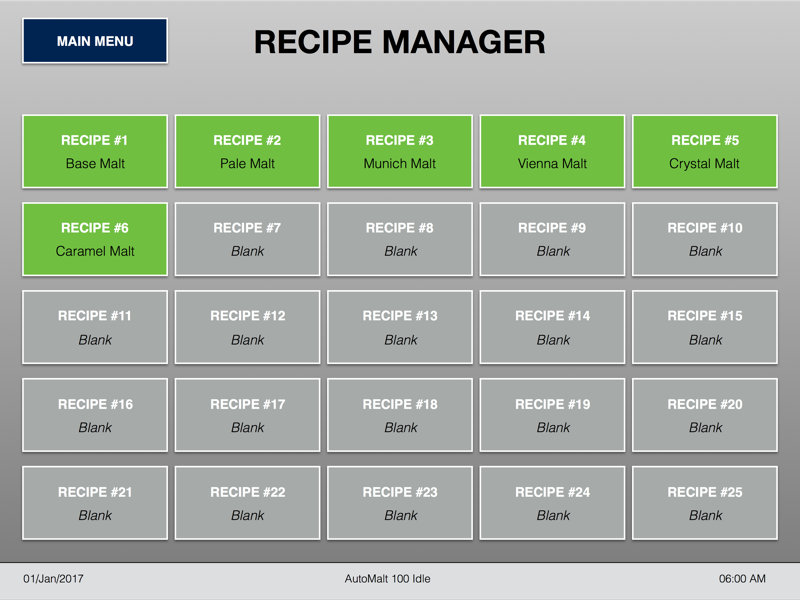

Full Automation

Our proprietary, graphics-based software package has been developed for use with an Allen Bradley industrial PLC and touch screen interface, resulting in a state-of-the-art control system that will work dependably for years.

Simple and secure access to system control screens is provided via a web-based interface. This means the process can be monitored and adjusted from anywhere in the world from a computer or mobile device. Email alerts can also be setup for notification of critical system alarms.

Over two-dozen recipes may be stored within the control system. Nearly every process setting (time, temperature, air flow, etc.) may be configured using multiple sub-stages to create customized, repeatable batching sequences for your various product lines.

A Rousing Success

A multi-level aeration manifold is installed on the tank cone to rouse the grain and raise dissolved oxygen levels in the steep water at adjustable intervals, duration and pressure for ultimate flexibility.

Flexible Controls

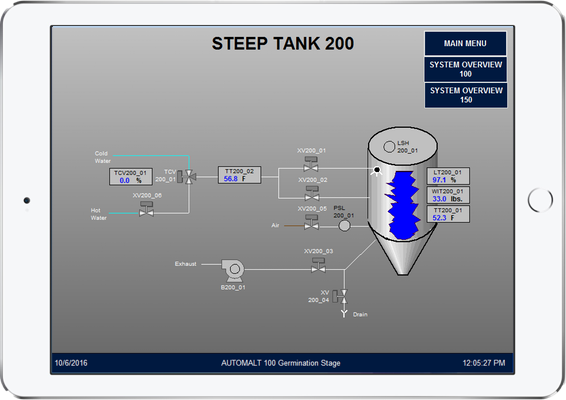

AutoSteep™ uses the same automation platform as the AutoMalt™, allowing the Maltster to create and store multiple recipes, execute batch sequences automatically, and access the system remotely for monitoring and adjustment. Controls may be stand-alone or integrated with downstream equipment such as the AutoMalt or AutoKiln for a single operator interface.

Tradition Meets Innovation

The food-grade stainless steel steeping vessel includes an industry standard 60º cone bottom to aid in the cast-out process. An innovative multi-nozzle spray ring installed around the upper lip of the vessel provides dust control during grain loading, directs water and debris towards the overflow weir during swim-out, and rinses down the vessel walls in-between batches to reduce cleaning efforts.

AutoSteep™ includes automatic valving and sensors for level control, temperature monitoring, and pressure regulation. This equipment integrates with the control system to automate the steeping process from water addition, through aeration, air-rest and CO2 extraction.

Full Access

The MiniMalt™ vessel includes two access doors on the upper head which provide full access for loading, grain turning, inspection and cleaning. The gasketed doors clamp shut when not in use to prevent process air leakage.

Unload WIth Ease

The MiniMalt™ vessel unloading door sits flush with the stainless steel wedge wire false bottom grating. This allows the finished malt to be easily swept or raked from the tank once the process is complete. The grate sections can be removed through this door to access the plenum chamber for cleaning or maintenance.