Welcome...

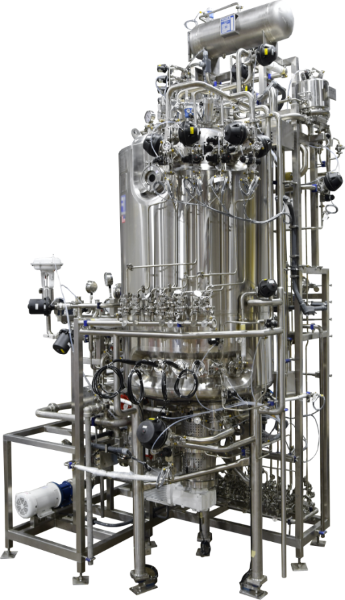

Bioreactor

IPEC Bioreactor and Fermentation Systems accommodate total customization, with unparalleled quality, for any industry.

Bioreactor

Scalability

Our systems effectively support complex and critical processing at nearly any scale, from small pilot operations to large-scale manufacturing.

150L

Bioreactor

Your Process

Each sub-system and component is examined and configured to suit process requirements, available utilities or customer preference.

1200L

Process Vessel

Every aspect of your vessel can be custom-designed, including:

- Working Volume & Aspect Ratio

- Materials of Construction & Surface Finish

- Heat Transfer

- Pressure & Temperature Ratings

- Process, Instrumentation & Sample Ports

- Spargers & Down Tubes

- Sight Glass & Light Glass

- Agitation-Style (top-mount/bottom-mount)

- Leg/Lug-Mount

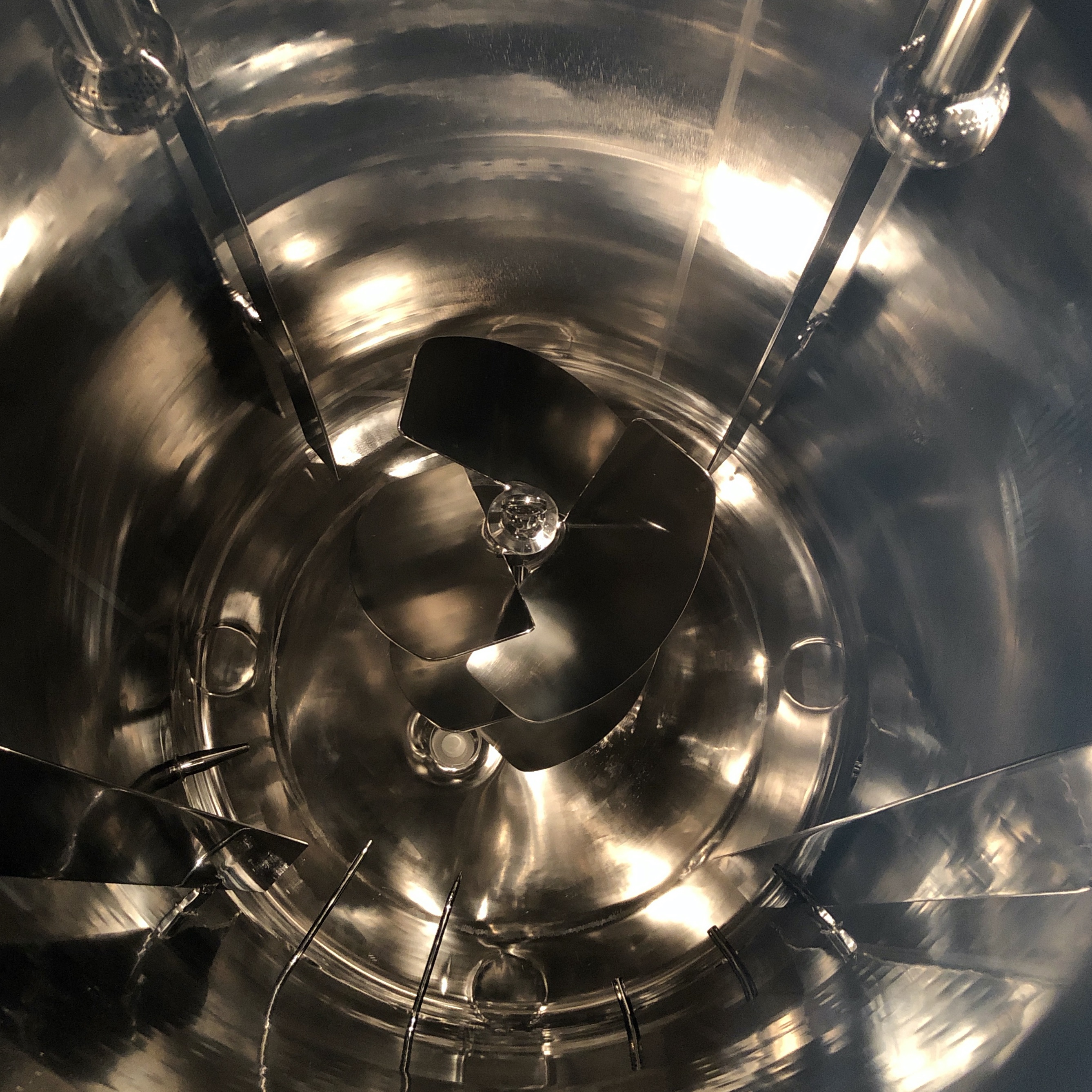

Mixing Systems

A number of options may be considered when configuring your agitator:

- Top-Mount vs. Bottom-Mount

- Mechanical Seal vs. Magnetic-Drive

- Qty/Style of Impellers (Turbine, High Solidity, BioProp, etc.)

- High/Low Shear, Mixing Speed, Pumping Rate, etc.

- Materials of Construction/Surface Finish

Instrumentation

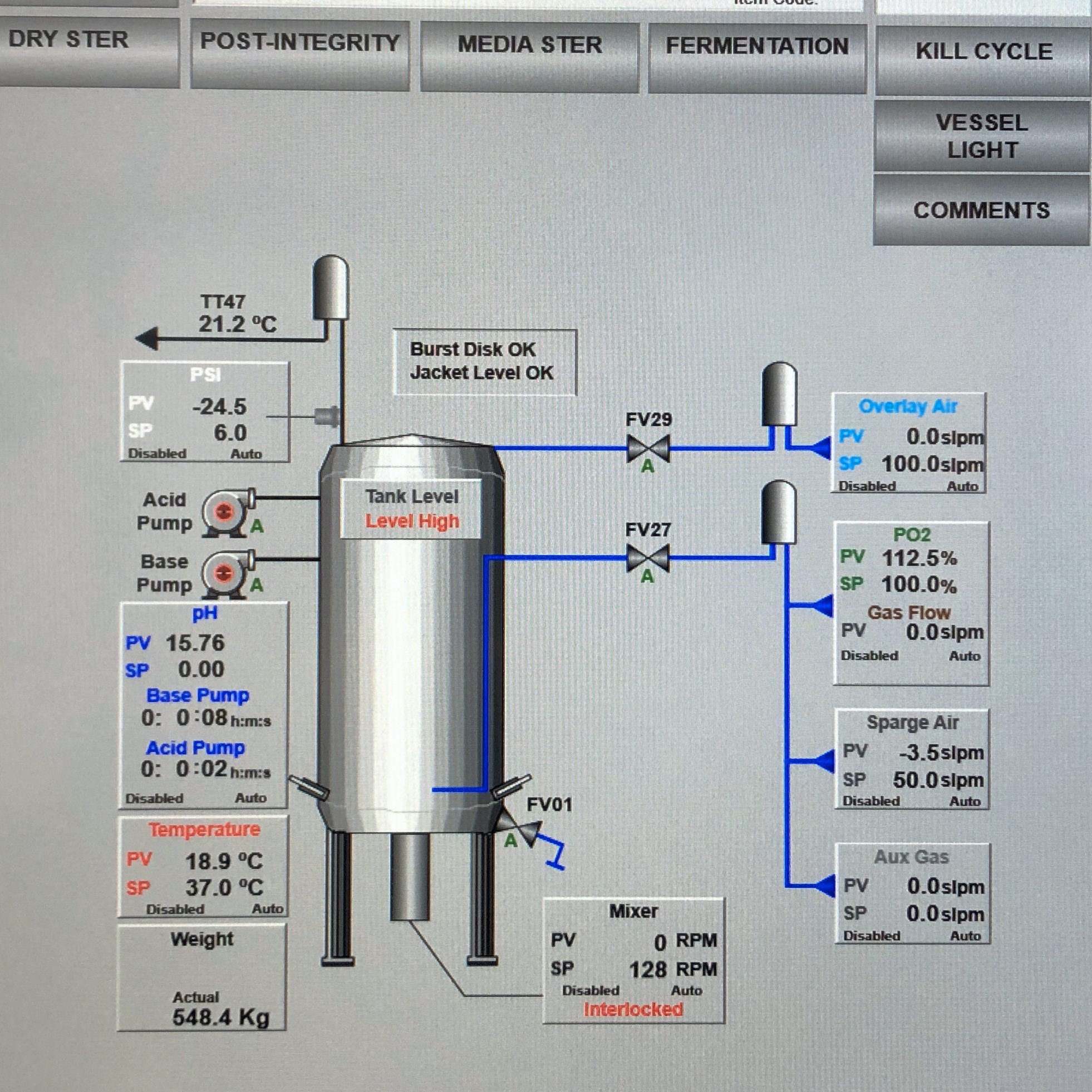

Any or all of the following process measurements can be incorporated:

- pH

- Dissolved Oxygen

- Temperature

- Conductivity

- Liquid Level/Weight

- Foam Detection

- Pressure

- Gas Flow

- Turbidity

- ORP/Redox

- Off-Gas Analysis

Additions

Steam Lock valve arrays are incorporated for additions, transfers, sampling, etc. at various locations on the vessel. These valves may be manually operated, but are typically automated for validated cleaning and sterilization.

Sampling & Harvest

Hygienic valves or other single-use/aseptic sampling devices may be mounted on the vessel.

Similarly, harvest solutions may be pumped or pressure transfered to downstream equipment or storage through stainless steel process or single-use tubing via aseptic fititngs.

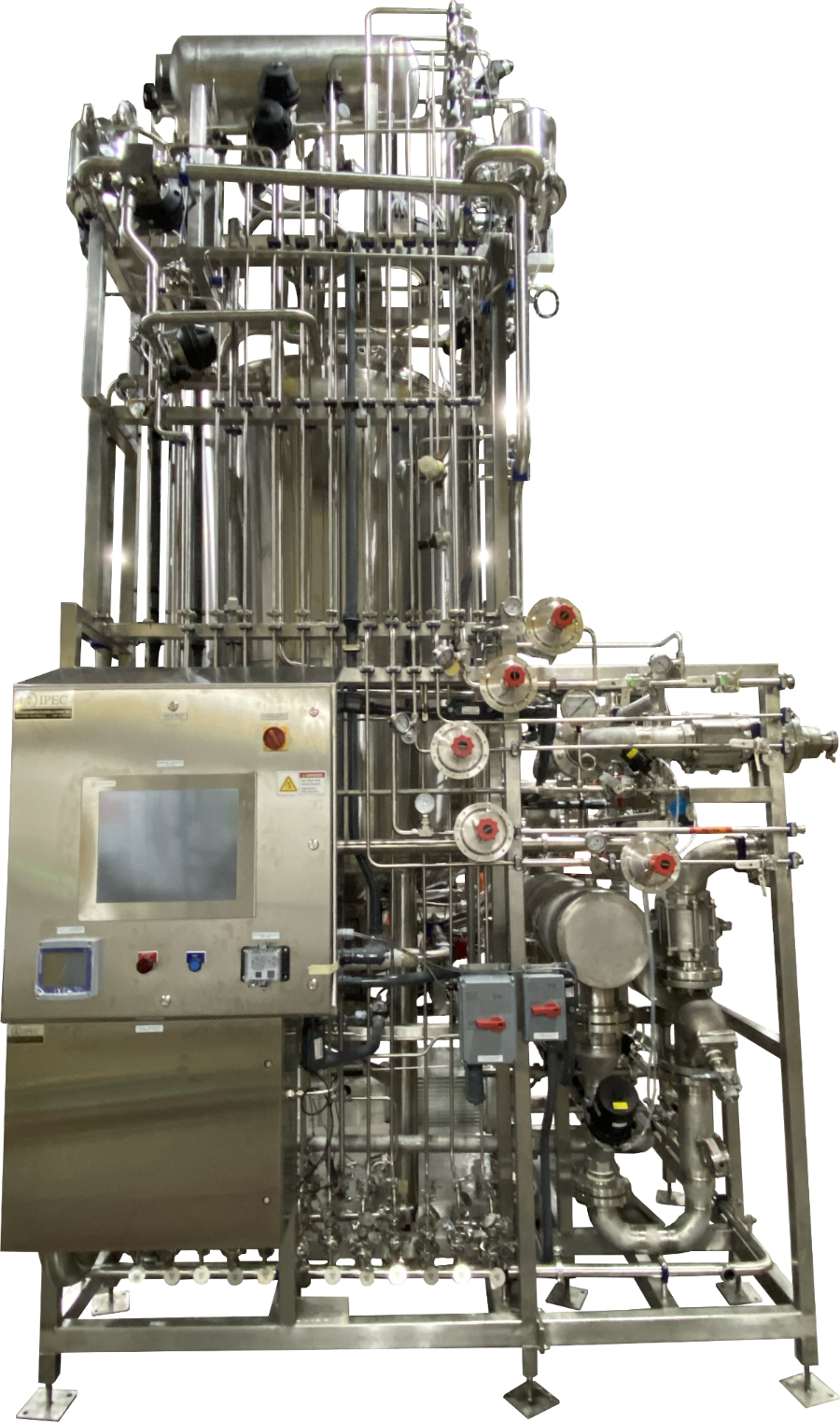

Custom Layout

After major components are specified and approved, IPEC begins system layout with considerations for available floor space, room layout, accessibility and customer work-flow. This eliminates compatibility issues with integration of pre-engineered desings into your facility. Proces/utility connectons, control panels/touch screens, instrumentation/sample locations and other items may be positioned for optimal efficiency.

Bioreactor

Your Design

Our collaboration with each customer results in unique systems delivering precise and dependable bioprocess operations.

2400L

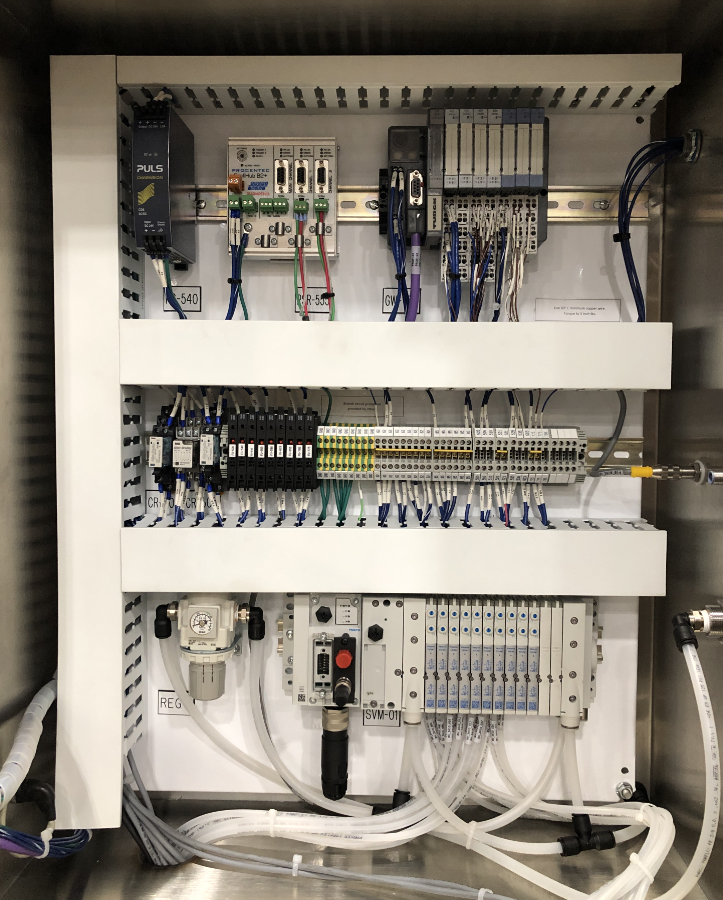

Control Systems

Our integrated control systems are cusomized based on process scope, customer specificaiton or preference, and may include:

- Local PLC/Controllers (Rockwell, Siemens, etc.)

- Remote I/O

- Bus Communications (AS-I, Fieldbus, DeviceNet, etc.)

- Pneumatics

- Power Conditioning

- Motor Controls

- Hazardous Environment Ratings

Automation

Automation platforms leverage previously developed routines for sub-sequences, etc., however each system includes custom software development which can integrate:

- Process Sub-Routines (mixing, temperature control, gassing, etc.)

- Recipe Management

- Alarms/Notifications

- 21 CFR Part 11 Compliance (security, audit trails, records, etc.)

- Integration with Plant Supervisory Networks/Controllers

- Report Generation (Cleaning, Sterilization, Presssure Test, Batch, etc)

Temperature Control

Each system can include an integral or stand-alone (remote) Temperature Control Modue to support bioprocessing activities. Unlike other suppliers who may offer limited configuration flexibility, IPEC systems are designed around your available utilities.

- Heating & Cooling Operations

- Steam Heating

- Electric Heating

- Hot/Cold Thermal Media

Gassing Schemes

Each Customer has their own gassing strategy which can significantly affect process design and complexity. As part of our collaborative design process, IPEC considers the following:

- Number of process gas types & associated supply pressures

- Minimum and maximum operational flow rates for each gas

- Flow path(s) for each gas (overlay, sparger, etc.)

- Gassing strategies (aeration, O2 enrich, additive flow, blended/ratio flow)

- Control strategies (vessel pressure control, pH/DO target, gas flow)

Steam Sterilization

IPEC bioreactor and fermentation systems are configured for efficient, validated steam-in-place for the sterile process boundary. Our designs are considerate of cost, safety and maintenance accessibility.

Component Manufacturers

While we are happy to supply components from our standard manufacturers, each customer is provided the opportunity to advise IPEC on their own preference for the following items (and more) for a truly customized system:

- Vessels

- Mixers

- Heat Exchangers

- Valves

- Steam Traps

- Instrumentation

- Controls Hardware

Bioreactor

A Complete Solution

Our goal as an equipment supplier is to provide customers with turnkey systems that exceed expectations and enhance your operations. Let us know how we can help today.

Fermentors, Bioreactors & Support Systems

Fermentation, Microbial/Cell Culture, Aerobic/Anerobic

Single/Multi-Stage

Media Prep, Heat Transfer, CIP Support Systems

Upstream & Downstream Single-Use Equipment

Bioreactor