Welcome...

Clean-In-Place

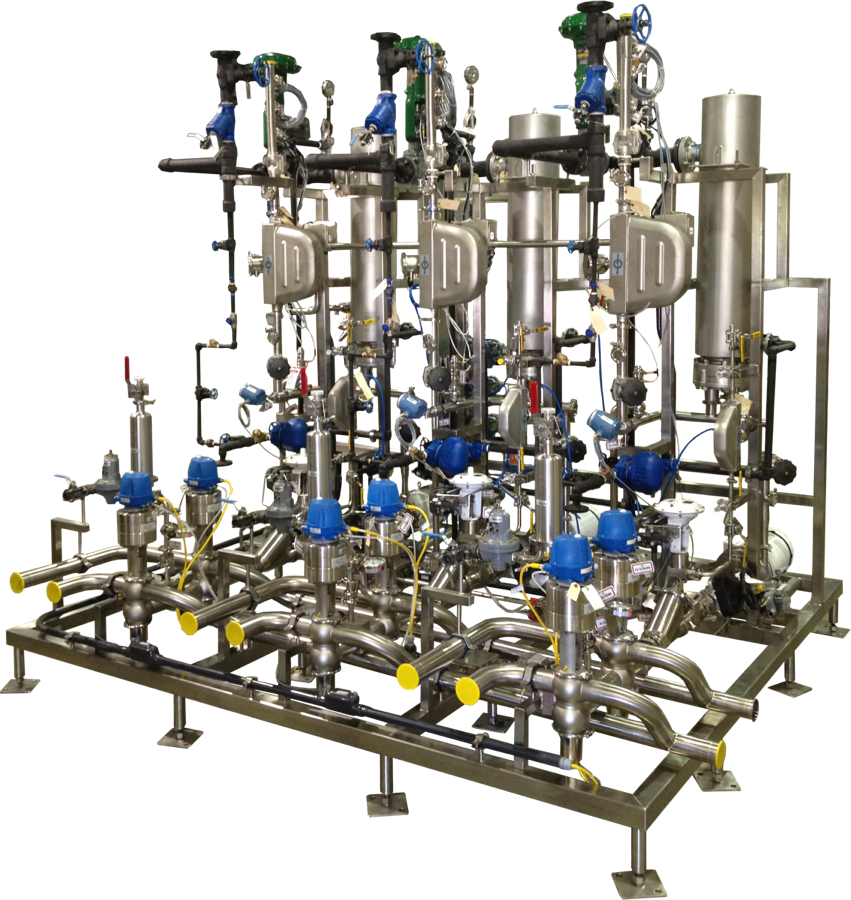

Repeatable and dependable cleaning is vital part of process development and manufacturing operations. IPEC is a global leader in design and fabrication of custom modular Clean-In-Place (CIP) Systems.

Clean-In-Place

Your Process

IPEC CIP skids are designed and optimized for each customer’s unique facility and cleaning requirements.

Clean-In-Place

Your Design

Tank sizing, instrumentation technologies and material/finish specifications are evaluated case-by-case to provide reliable, yet cost-effective equipment.

Pumps

CIP Supply Pumps are designed to provide sufficient flow and pressure based on facility piping, downstream equipment and associated spray devices. CIP Return Pumps are available in stationary or portable configurations.

Wash Vessels

Wash Vessels are sized based on CIP circuit volume and any considerations for the downstream equipment. These tanks can be atmospheric (non-code) or rated pressure vessels and can be configured in a number of ways to support the cleaning process or customer preference (insulation, manways, vents/filters, pressure/temperature/level sensors, etc.).

CIP assemblies are also available with single wash/rinse vessels, or as tankless (once-through) systems.

Rinse Vessels

Rinse Vessels are sized based on feedwater flow rates and the requirements of the downstream equipment (spray devices or other rinsing considerations). These tanks can be atmospheric (non-code) or rated pressure vessels and can be configured in a number of ways to support the process or customer preference (insulation, manways, vents/filters, pressure/temperature/level sensors, etc.).

CIP assemblies are also available with single (combined) wash/rinse vessels, or as tankless (once-through) systems.

Heat Exchangers

Heat exchangers adjust and maintain CIP wash and rinse solution temperature to specification. Most commonly using steam for heating, electric options are also available. Each heat exchanger is custom-sized based on available utilities and required performance.

Flow Meters

Flow Meters (along with pressure sensors) are used to monitor and control the supply of CIP wash and rinse solutions to the downstream equipment and are critical for system validation. There are a number of styles/technologies available for consideration based on customer preference or specifications.

Analytical Instrumentation

CIP systems typically use analytical instrumentation to verify detergent solution concentration and as confirmation of successful final rinse. Conductivity probes are most commonly used for this purpose, however certain systems also incorporate pH, total organic carbon (TOC) or other analytical instrumentation based on customer or other regulatory demands.

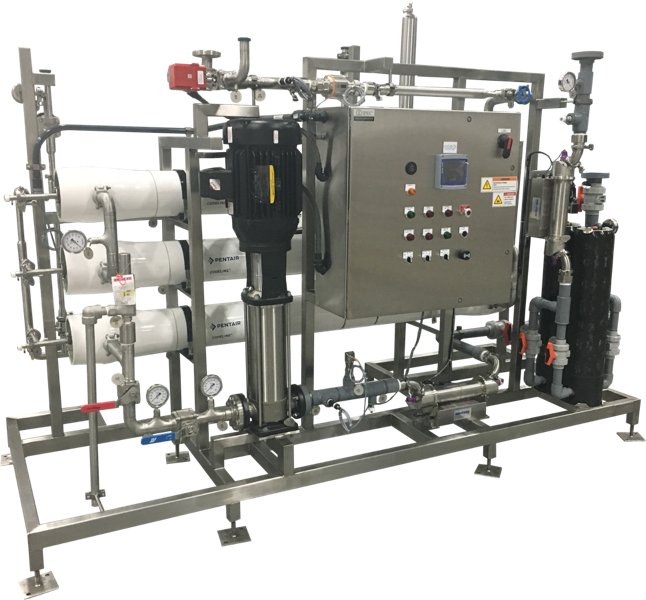

Automation

Each IPEC CIP automation system is customized for the specific process or customer-preference. Fully automated systems can be provided using a variety of PLC platforms. For facilities with supervisory control systems, distributed I/O can be networked to allow remote operation. Systems may be configured to comply with 21 CFR Part 11 requirements or to provide other record/reporting functions.

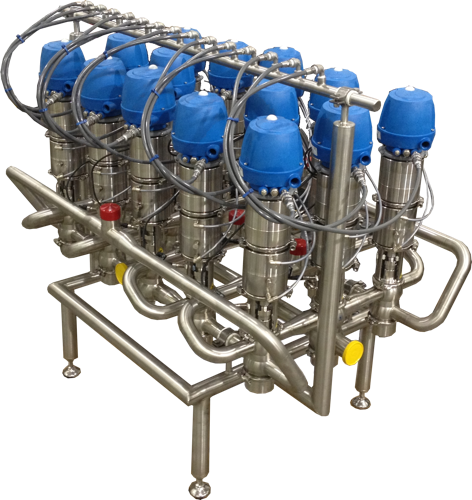

System Valving

CIP system valve style and configuration may vary by industry or customer-preference. As part of our standard design process, IPEC will review options for make, model and optional/alternate configurations to provide each customer an opportunity to consider their best solution.

Clean-In-Place

Operational Efficiency

IPEC CIP Systems are designed and built for efficient use of water, chemicals, and energy. Our customers rely on dependable and repeatable results to minimize production downtime.

Clean-In-Place

Portability

If additional facility piping cannot be accommodated, or you simply demand greater flexibility, IPEC Portable CIP Systems or Return Pump Carts are the solution.

Clean-In-Place

Specialty

When it comes to Clean-In-Place, IPEC has seen it all. Our experienced staff can guide you through engineering and design options when special circumstances require non-traditional solutions.

Clean-In-Place